We promote progressive integration of innovative technologies into traditional construction practices to enhance quality, site safety sustainability and operational efficiency in our projects, with a vision to support and help drive the digital transformation of the local construction industry.

The Construction Industry Council has approved it as one of its official Biometric Access Control Systems. Its face recognition and artificial intelligence technologies eliminates administrative time spent on accessing and recording staff information. It also enhances processing by providing access to real-time worker information and accurate site attendance records through a mobile or web application. Further, it enhances site security management and allocation of human resource.

The Group has adopted ultra-wideband technology, 5G and IoT technology to optimise the existing safety management system. Real-time positioning tracking system and anti-collision system ensures a safe operating distance from different machines to workers by detecting risks from sensors on smart helmets, cards and wristbands, keeping them away from hazards with the aid of vibration prompt, audible and visual warnings.

The Group has deployed a robotic wall painting machine in our projects to promote a safe and clean painting process with most of the high-risk manual painting works replaced.

Remote monitoring and controlling enables multi-collaboration at different locations and provides a high standard of painting quality performed with the nozzle injection amount and angle control.

Gold Medal winner at the 44th International Exhibition of Inventions of Geneva.

The ability to plaster sections of the wall up to a height of 5 metres above ground increases productivity while reducing material waste and further minimising the risk of working at height.

Smart Enertainer adopts an advanced energy storage system to replace two sets of diesel generators (400A) in powering up construction equipments. Not only does it reduce the consumption of diesel fuel resulting in lowered level of air pollution and carbon emission but also reduces noise pollution during operation.

The Group adopts 3D scanners to check alignments, flatness and levels of the works, such that MiC units can be installed speedily resulting in fast construction completion and accurate productions of as-built drawings. It can be adhered to excel the agreed schedule and further proceed amongst different hold point stages in the construction process.

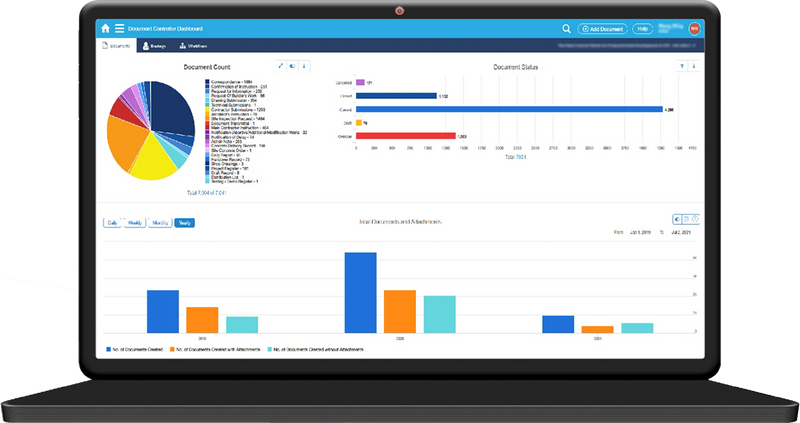

PMIS is a platform developed to manage construction projects. As a document management system, our clients, sub-contractors and architects can view, store and generate documents for approval or reference, uplifting the workflow efficiency and increases the transparency throughout the project management process.

An integrated platform that synchronises information from all other applications providing clear overviews of project status, our clients can monitor the progress of their project and have a quick glimpse of the critical KPIs through in-app dashboards on their mobile anytime and anywhere.

The Group has widely adopted a cloud-based real-time drawing management system and construction productivity software at its sites, aimed at reducing the use of paper drawings and facilitating task management. It enables real-time sharing, update and seamless synchronization to all users with all-version markup and photo plugin.

The Group develops the A.I. Site Monitoring System for site safety. Through real-time images captured from CCTV cameras on site, the system’s powerful A.I. algorithm can recognise different objects and scenarios and analyse the safety of their situation. The system can immediately alert the safety officer and management to prevent potential accident occurring.

The Group adopts the use of Hololens for demonstrating and visualising planned building work through mixed reality and BIM. With clear illustrations and real time on-site demonstration, it can minimise design changes and detect clashes instantly.

Our team leaders can jointly review and monitor construction sequences including logistics planning, material deliveries and installation while keeping track of progress and making critical decisions through romote meetings to speed up construction.

Our self-developed cloud platform “VisionHub” – 360-degrees, image-oriented platform for safety training and monitoring allowing documents to be accessible anytime. It is beneficial for specific safety training courses involing high-risk work activities such as working in confined spaces, underground excavation and heavy lifting.

The Group has deployed Mobile Immersive VR Device for safety training - the first immersive VR suitable for deployment on-site in low-headroom situations. The device enhances the effectiveness of site safety supervision by building on the experience of multiple users.

The Group utilises Augmented Reality technologies for modern site management by using a variety of interactive digital environment and BIM data and overlays on the real world so that users can interact with it.

We have self-developed the first mobile AR App in the local construction industry for safety inspection such as checking lifting operations to deploy on-site in low-headroom situations.